Craftsmen Maintenance Limited Earns NCAA AMO Certification for Large Aircraft Maintenance

Lagos, Nigeria – In a major leap for Nigeria’s aviation industry, Craftsmen Maintenance Limited has been officially approved and certified by the Nigeria Civil Aviation Authority (NCAA) as an Approved Maintenance Organisation (AMO), specializing in large aeroplane maintenance. This certification marks a significant step forward in enhancing aviation safety, compliance, and service quality in the West African sub-region.

What the NCAA Certification Means

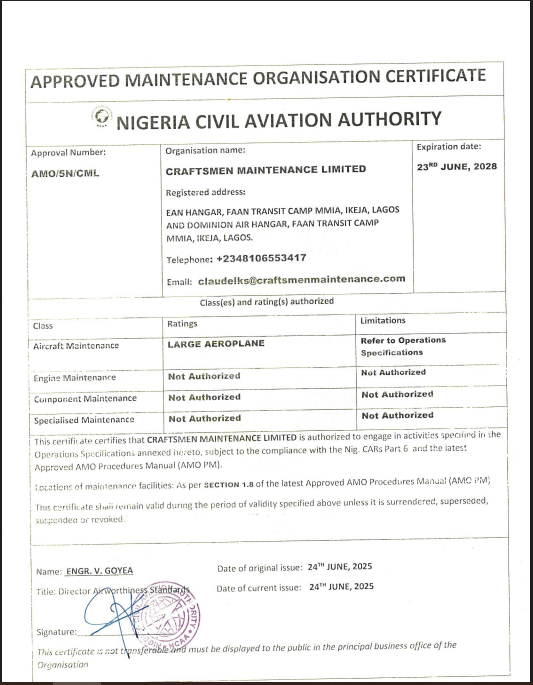

The NCAA AMO certification, with approval number AMO/5N/CML, confirms that Craftsmen Maintenance Limited is authorized to carry out maintenance on a range of large aircraft under stringent Nigerian Civil Aviation Regulations (Nig. CARs) Part 6.

With an expiry date set for 23rd June 2028, this five-year certification ensures long-term operational capability for Craftsmen Maintenance Limited, giving airline operators and stakeholders added confidence in the company’s expertise and regulatory compliance.

Aircraft Types Covered Under Approval

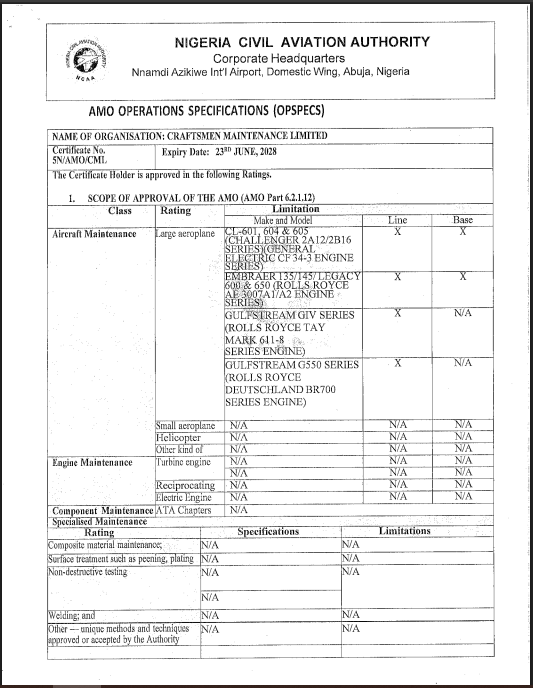

According to the AMO Operations Specifications (OPSPECS) provided by the NCAA, Craftsmen Maintenance Limited is authorized to maintain the following aircraft types at both Line and Base Maintenance levels:

Bombardier Challenger 601, 604, 605, 212/2B16

Electric CF 34-3 Engine Series

Embraer Legacy 600 & 650 (Rolls Royce AE 3007A/A2 Engines)

Gulfstream GIV Series (Rolls Royce TAY 611-8 Engines)

Gulfstream G550 Series (Rolls Royce BR700 Series Engines)

This wide range of coverage demonstrates the company’s technical versatility and capacity to serve a diversified clientele in both business and commercial aviation sectors.

Craftsmen Maintenance Limited operates out of EAN Hangar, FAAN Transit Camp MMIA, Ikeja, Lagos and Dominion Air Hangar, ensuring proximity to major aviation operations at Murtala Muhammed International Airport (MMIA), Lagos—one of the busiest airports in West Africa.

With this certification, Craftsmen Maintenance Limited becomes a key player in domestic aircraft maintenance services. This not only reduces dependency on overseas MRO (Maintenance, Repair, and Overhaul) facilities but also creates employment opportunities for licensed aircraft engineers and supports the Nigerian government’s drive for local capacity development in aviation.

Craftsmen Maintenance Limited’s NCAA certification is a testament to the company’s commitment to international aviation safety standards, operational integrity, and technical proficiency. As the aviation industry in Nigeria continues to grow, the role of certified AMOs like Craftsmen Maintenance Limited will be central to sustainable development and global competitiveness.